SEALEXCEL INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SEALEXCEL INDIA P.LTD.

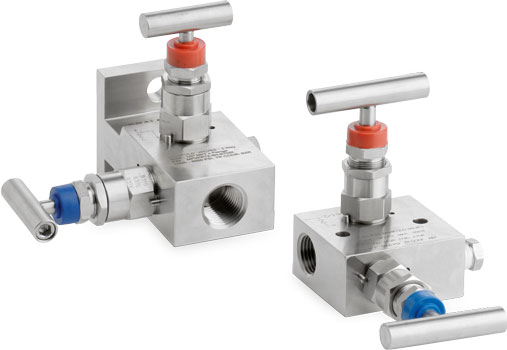

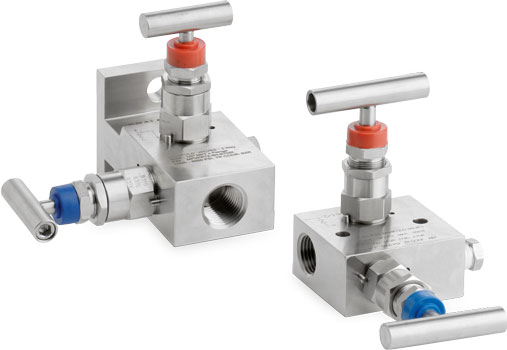

Manifold Valves

We are the trusted name in the industry when it comes to the manufacture and supply of valves, fittings and industrial couplings with adapters. We have served a wide variety of industrial sectors, and supply products which conform to industry standard requirements and ensure safety and system efficiency with their precision design.

We offer an extensive product portfolio, and are also trusted manifold valve manufacturers, who offer reliable products for high end system efficiency. We understand the importance of durable quality in industrial valve and fitting design, and that is why we never compromise on quality.

Key Features of Our Manifold Valve Units

Some of the key features of our superior quality high precision manifold valve design are,

Units duly designed to withstand system static pressure.

The manifold valves are manufactured to endure all differential pressure and liquid level application needs.

Units have been manufactured according to a compact assembly design. This translates into complete products which have a reduced weight and size.

The design and manufacturing details of the valve manifold units ensure fewer chances of potential leak points.

All units undergo extensive testing procedures to assess quality and precision before being supplied to customers.

Units are available in a stainless steel 316 material series design.

The units have been manufactured to ensure easy installation and hassle free maintenance in aggressive industrial systems.

The units are available in 2 valve manifold, 3 valve manifold, and 5 valve manifold product designs.

The 2 valve units are designed to withstand static pressure in an industrial setting.

The 3 level and 5 level valve units are expressly designed for the purpose of surviving and maintaining the differential pressure applications.

The units have been designed with a temperature rating with operating parameters which range up to 232ºC with packing of PTFE and optional 428ºC with packing of graphite.

The units are designed and manufactured to withstand a pressure parameter rating of up to 6000 PSIG.

Click here to download details about manifold valve units and their design options for use in a variety of industrial settings.

Our High Precision Superior Quality Manifold Valves

We make sure that all manifold valve units that reach our diverse industrial customers, are of high material and design quality, completely free of any kind of flaw or operating error.

We have highly sophisticated testing facilities, and use different methods to gauge the working quality of our products.

Our standard test for manifold valve units is factory tested with nitrogen at 1000 psig (69 bar) for leakage at the seat and packing, the maximum allowable leak rate of 0.1 sccm and Hydrostatic test is optional. This test is performed with de-ionised water at 1.5 times the working pressure, to make sure that the our 2, 3 and 5 valve manifold units are all up to the mark of industrial quality that we promise our customers. We never settle for anything less than the very best in product design and quality and only offer safe, perfectly functioning, superior quality parts which ensure efficiency in all types of aggressive industrial settings and systems.

Contact us or click here to access for more information of our product portfolio, and order industrial valves and fittings, which will boost up and secure your system efficiency and systems.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.